Western Welder: Forging Excellence In Safety & Craftsmanship

In the demanding world of welding, where sparks fly and precision is paramount, the right gear isn't just a luxury—it's a lifeline. This is where the name "Western Welder" resonates with a promise of unparalleled quality, robust protection, and a deep understanding of the craft. More than just a brand, it represents a commitment to the men and women who shape metal with fire, providing them with the tools, training, and attire they need to perform at their peak, safely and effectively.

From the foundational triple-stitched fabrics that guard against intense heat to the advanced machinery that enables intricate custom fabrication, "Western Welder" encompasses a spectrum of excellence. It's about a legacy built on decades of hands-on experience, an unwavering focus on the welder's needs, and a dedication to fostering the next generation of skilled artisans. This article delves into the multifaceted world of Western Welder, exploring its dedication to quality, its comprehensive services, and its pivotal role in the welding community.

Table of Contents

- The Unyielding Commitment to Quality: Western Welder Outfitting

- Beyond Apparel: Advanced Fabrication & Repair Capabilities

- The Welder's Perspective: Understanding Your Needs

- Cultivating Expertise: The Western Welding Academy Difference

- The Legacy of Durability: Decades of Service

- Safety First: Why Quality Gear is Non-Negotiable

- Locating Excellence: Western Welder's Reach

The Unyielding Commitment to Quality: Western Welder Outfitting

When you're working with molten metal and intense heat, your protective gear isn't just clothing; it's your first line of defense. This is precisely why Western Welder Outfitting stands out. They don't just make welding outfits; they craft safety gear designed with the highest standards in mind. Their commitment to quality is evident in every stitch, every fabric choice, and every design detail.

The core of their offering lies in their "highest quality triple stitched fabrics welding outfits & safety gears like welding shirts, gloves, arm pads, and hats." This isn't just marketing jargon; it's a critical safety feature. Triple stitching ensures durability, preventing seams from failing under stress and prolonging the life of the garment. In a profession where a single spark can cause severe burns, this level of reinforcement provides peace of mind. It reinforces the understanding that "there's no substitute for quality and protection on the job." While you might find fashionable shirts from top brands elsewhere, for the rigors of welding, specialized and rigorously tested gear is non-negotiable.

The product range from Western Welder Outfitting is comprehensive, covering all essential protective wear. "Their product range includes triple stitched fabric welding shirts, gloves, arm pads, and hats." Each item is designed to offer maximum protection without compromising comfort or mobility. This dedication to superior materials and construction has cemented their reputation as a "legitimate and reputable online store specializing in workwear for welders." Their emphasis isn't just on selling products, but on providing essential tools that safeguard a welder's health and career.

Beyond Apparel: Advanced Fabrication & Repair Capabilities

The expertise associated with the "Western Welder" name extends far beyond just protective clothing. It encompasses a robust capability in custom fabrication and repair, showcasing a deep understanding of metalwork itself. Companies operating under this ethos are equipped to handle complex projects, from intricate custom designs to heavy-duty industrial repairs.

A prime example of this advanced capability is seen in services like "Custom welding and semi trailer repair." This isn't a task for just any shop; it requires specialized equipment and highly skilled welders. The presence of a "5x10 plasma table, 250 ton press brake, and machining equipment" speaks volumes about the scale and precision of work that can be undertaken. A plasma table allows for accurate and efficient cutting of metal sheets, while a press brake is essential for bending and forming heavy gauge materials, crucial for trailer repairs and custom fabrications. Machining equipment further enables the creation of custom parts and precise finishing, ensuring every component fits perfectly and functions flawlessly.

Furthermore, the ability to "weld carbon, aluminum, and stainless steel" demonstrates versatility and expertise across different metal types, each requiring specific techniques and knowledge. Carbon steel is common in structural work, aluminum requires specialized MIG or TIG welding due to its properties, and stainless steel demands careful handling to prevent contamination and maintain its corrosion resistance. This breadth of material expertise ensures that a wide array of client needs can be met with the highest standards.

This comprehensive service offering is often backed by significant experience. For instance, some entities have been offering "welding (mig, tig & portable) fabrication and repairs" since as early as 1971, highlighting a long-standing commitment to the industry and a deep reservoir of practical knowledge.

Precision Techniques: Mastering the Arc

The world of welding is diverse, with various techniques suited for different applications and materials. Entities aligned with the "Western Welder" standard "specialize in a wide range of welding techniques." This mastery is crucial for delivering high-quality results across diverse projects.

Key among these techniques are MIG (Gas Metal Arc Welding) and TIG (Gas Tungsten Arc Welding). MIG welding is known for its speed and efficiency, often used for thicker materials and production work. TIG welding, on the other hand, offers unparalleled precision and clean welds, making it ideal for thinner materials, intricate designs, and applications where aesthetics are critical, such as stainless steel fabrication. The inclusion of "portable" welding services further enhances their versatility, allowing them to bring their expertise directly to job sites, which is invaluable for large-scale repairs or installations that cannot be moved to a shop.

Mastery of these techniques, combined with state-of-the-art equipment, ensures that every weld is strong, durable, and meets the specific requirements of the project. This level of technical proficiency is what sets true experts apart in the field of metal fabrication and repair.

The Welder's Perspective: Understanding Your Needs

What truly sets the "Western Welder" philosophy apart is its profound empathy for the end-user. It's not just about selling products or services; it's about a shared experience. The statement, "At western welder, we know what you need because we've been where you are," isn't just a marketing slogan—it's a testament to their roots. Many involved in these operations have spent years on the shop floor, under the hood, and in the field, facing the same challenges and demands as their customers.

This intimate understanding translates directly into the design and functionality of their products and the efficiency of their services. They understand the grueling hours, the uncomfortable positions, and the constant threat of injury. This first-hand experience drives their commitment to ensuring "there's no substitute for quality and protection on the job." They know that a poorly fitting glove or a shirt that quickly degrades can not only hinder performance but also jeopardize safety. This personal connection builds immense trust and loyalty among welders.

Beyond pure functionality and safety, there's also an acknowledgment of personal pride. "And we know you want to look good." While safety is paramount, welders also appreciate gear that is well-designed, comfortable, and reflects their professionalism. This attention to detail—combining robust protection with a professional aesthetic—is a subtle yet significant aspect of their appeal. It’s this blend of practicality, protection, and personal connection that defines the "Western Welder" ethos.

Cultivating Expertise: The Western Welding Academy Difference

The "Western Welder" ecosystem isn't just about providing gear and services; it's also deeply invested in shaping the future of the welding industry through education. The "Western Welding Academy" (WWA) stands as a beacon in this regard, embodying the highest standards of training and skill development.

What makes WWA truly unique is its ownership and operation model: "Western welding academy is the only pipe welding school in the country that is solely owned and operated by real pipeline/pipe welders." This is a critical distinction. Learning from instructors who have actually worked in the demanding field of pipeline welding provides students with invaluable real-world insights, practical techniques, and an understanding of industry expectations that classroom-only instructors simply cannot offer. This direct lineage from experienced professionals ensures that the curriculum is always relevant, practical, and up-to-date with the latest industry standards and challenges.

The result? WWA produces "the most elite, highest skilled welders" in the country. Their focus on hands-on training, rigorous practice, and mentorship from seasoned professionals equips graduates with the confidence and competence to excel in one of the most challenging and rewarding sectors of the welding trade. For anyone considering a career in pipe welding, an institution like WWA represents an investment in top-tier education and a direct pathway to becoming a highly sought-after professional.

Bridging Education and Industry: Advanced Manufacturing Programs

The specialized training offered by institutions like Western Welding Academy is part of a broader trend towards advanced manufacturing education. These programs are vital for feeding the pipeline of skilled labor into various industries that rely heavily on precision and technical expertise.

Examples like "Advanced manufacturing programs at western maryland works include, Machining, welding, robotics, industrial maintenance, heavy machinery, & more!" illustrate the comprehensive nature of modern industrial training. Welding is often just one component of a larger skillset required in advanced manufacturing environments. Understanding robotics, industrial maintenance, and heavy machinery operations allows welders to be more versatile and valuable assets to any company. These integrated programs ensure that graduates are not just proficient in a single skill but are well-rounded technicians capable of adapting to the evolving demands of the manufacturing sector. This holistic approach to education ensures that the workforce is not only skilled but also resilient and adaptable, a crucial factor for the industry's continued growth and innovation.

The Legacy of Durability: Decades of Service

Longevity in any industry is a strong indicator of reliability and quality. The "Western Welder" narrative is often intertwined with businesses that have stood the test of time, some operating for over half a century. For instance, the reference to services available "Since 1971" for welding, fabrication, and repairs, or even the mention of "Vermeer hay equipment, sales, parts & service since 1978," speaks volumes.

While Vermeer hay equipment might seem tangential to welding outfits, its inclusion highlights a regional characteristic of enduring businesses that serve demanding, hands-on industries. Both examples point to a heritage of providing essential, durable equipment and services that withstand the rigors of heavy use and time. This long-standing presence in the market builds immense trust. Customers know that a business operating for decades has proven its commitment to quality, customer service, and adapting to industry changes. This legacy of durability is a cornerstone of the "Western Welder" reputation, assuring clients that they are dealing with established experts who understand the long-term needs of their craft.

Safety First: Why Quality Gear is Non-Negotiable

In the dangerous world of welding, safety is not merely a recommendation; it's an absolute imperative. The risks are substantial: intense UV radiation, extreme heat, flying sparks, molten metal, and hazardous fumes. Investing in high-quality protective gear from a reputable source like "Western Welder" isn't an option—it's a critical component of a welder's personal safety strategy. This is where the YMYL (Your Money or Your Life) principle comes into sharp focus; the choices made regarding welding safety directly impact one's health and financial well-being.

Inferior welding gear can lead to severe consequences. A shirt made from non-flame-resistant material can ignite, causing severe burns. Gloves that lack proper insulation or durability can result in painful contact burns or cuts. Even seemingly minor items like hats and arm pads play a crucial role in protecting vulnerable areas from sparks and spatter. This is why the emphasis on "highest quality triple stitched fabrics" is so vital. Such materials and construction methods are designed to withstand the harsh welding environment, providing a reliable barrier between the welder and potential hazards.

Beyond immediate protection, quality gear also contributes to long-term health. Proper eye protection prevents arc flash, which can lead to permanent vision damage. Adequate ventilation and respiratory protection safeguard against inhaling toxic fumes, which can cause respiratory illnesses. By prioritizing quality and protection, welders not only safeguard their immediate well-being but also invest in their long-term health and ability to continue their craft.

Choosing Your Gear: A Practical Guide

When selecting welding gear, several factors should guide your decision, always with safety and quality at the forefront. Begin with the basics: a "Fr classic western welding shirt" or "fr lightweight summer tees" are essential. "FR" stands for flame-resistant, a non-negotiable feature for any welding apparel. Look for certifications and clear labeling that indicate the garment meets safety standards.

Next, consider the fit and comfort. While protection is key, ill-fitting gear can hinder movement and lead to fatigue, potentially increasing the risk of accidents. Quality brands like those associated with "Western Welder" understand this balance, designing gear that offers both robust protection and ergonomic comfort. Always check the stitching—triple stitching, as emphasized by Western Welder Outfitting, is a hallmark of durability and superior protection.

Don't overlook accessories like gloves, arm pads, and hats. Gloves should offer dexterity while providing ample heat and abrasion resistance. Arm pads add an extra layer of protection for forearms, especially during overhead welding. A welding hat, often worn under the helmet, protects the scalp and neck from sparks and UV radiation. Remember, every piece of gear plays a role in your overall safety system. Investing in the best quality you can afford is an investment in your health and career.

Locating Excellence: Western Welder's Reach

The presence and accessibility of quality welding services and products are crucial for professionals across the country. While "Western Welder" might refer to a collective ethos or a specific brand, its principles are embodied by various entities committed to the craft. For example, a company like "Zuroweste Welding LLC is located at 1921 County Rd 156 in Auxvasse, Missouri 65231." This specific location highlights the importance of local, reputable businesses that provide essential welding services and products within communities.

Whether it's a local fabrication shop offering custom solutions, an online store providing top-tier safety gear, or a specialized academy training the next generation of welders, the reach of the "Western Welder" commitment is extensive. These entities, regardless of their specific name or location, share a common thread: a dedication to quality, expertise, and supporting the welding community. They ensure that professional welders, from those working on pipelines to those in custom fabrication shops, have access to the best tools, training, and protective equipment necessary to perform their demanding jobs safely and effectively.

Conclusion

The name "Western Welder" encapsulates a comprehensive commitment to the art and science of metalworking. It represents not just a supplier of equipment or apparel, but a partner in the demanding journey of a welder. From providing "highest quality triple stitched fabrics welding outfits & safety gears" that ensure unparalleled protection, to offering advanced fabrication and repair services utilizing state-of-the-art equipment like "5x10 plasma tables" and "250 ton press brakes," the dedication to excellence is clear.

Moreover, the personal understanding—"we know what you need because we've been where you are"—fosters a deep trust, while institutions like the "Western Welding Academy" ensure the legacy of skilled craftsmanship continues through elite training. In a profession where safety and precision are paramount, "Western Welder" stands as a testament to quality, expertise, and an unwavering commitment to the well-being and success of every welder. Investing in the principles and products associated with Western Welder is an investment in your safety, your craft, and your future.

Are you a welder who prioritizes quality and safety? Share your experiences with top-tier gear in the comments below, or explore the comprehensive solutions offered by reputable Western Welder-aligned entities to elevate your craft and protection.

- Hotel Groove Shinjuku

- South County Mall

- Chris Isaak Songs

- Embassy Suites By Hilton San Diego Bay Downtown

- John Stamos Tv Shows

100 Best Western Movies of All Time To Watch At Home | Stacker

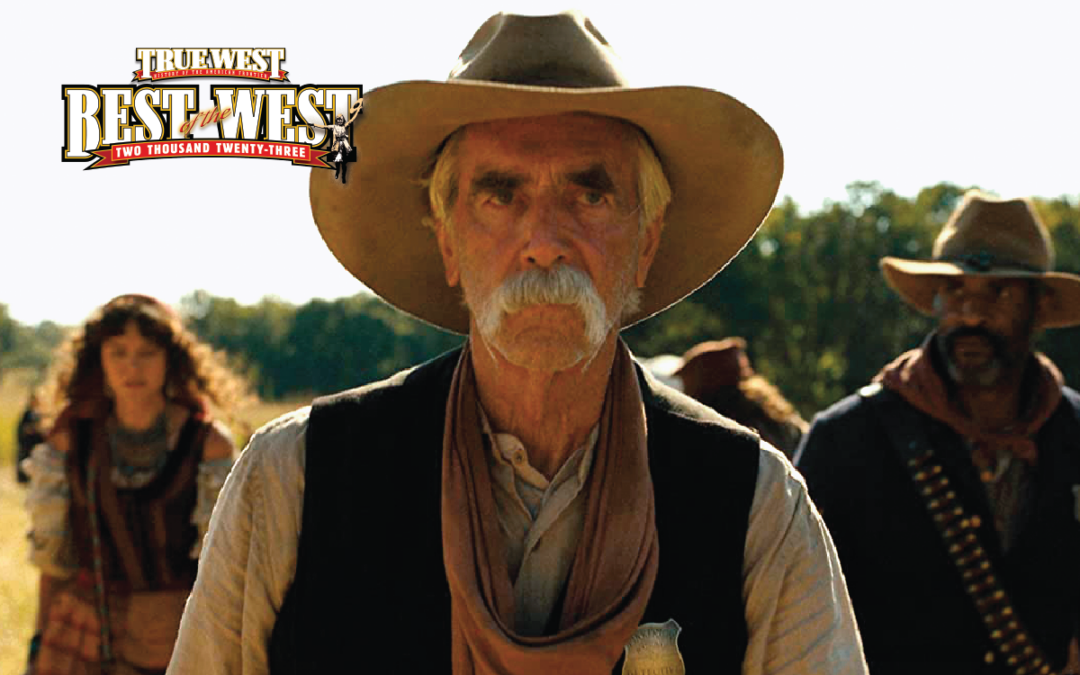

Best of the West 2023: Western Movies, DVDs & TV Shows - True West Magazine

Image gallery for Butcher's Crossing - FilmAffinity